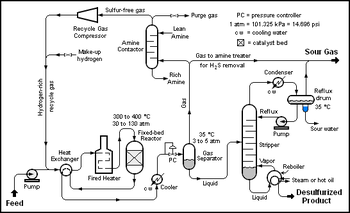

Ethane Cracker Process Flow Diagram

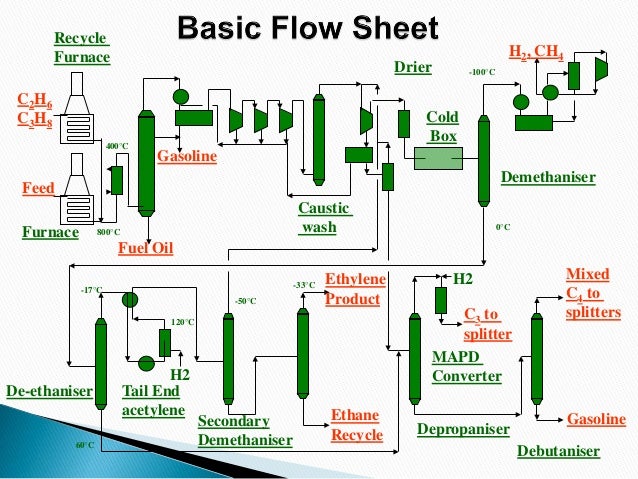

Simulation and analysis of ethane cracking process. Image courtesy of cbi in ethane cracking fresh feedstock and recycled ethane are thermally cracked in the presence of steam in a bank of pyrolysis furnaces.

Catalysts Free Full Text Olefins From Biomass Intermediates A

Catalysts Free Full Text Olefins From Biomass Intermediates A

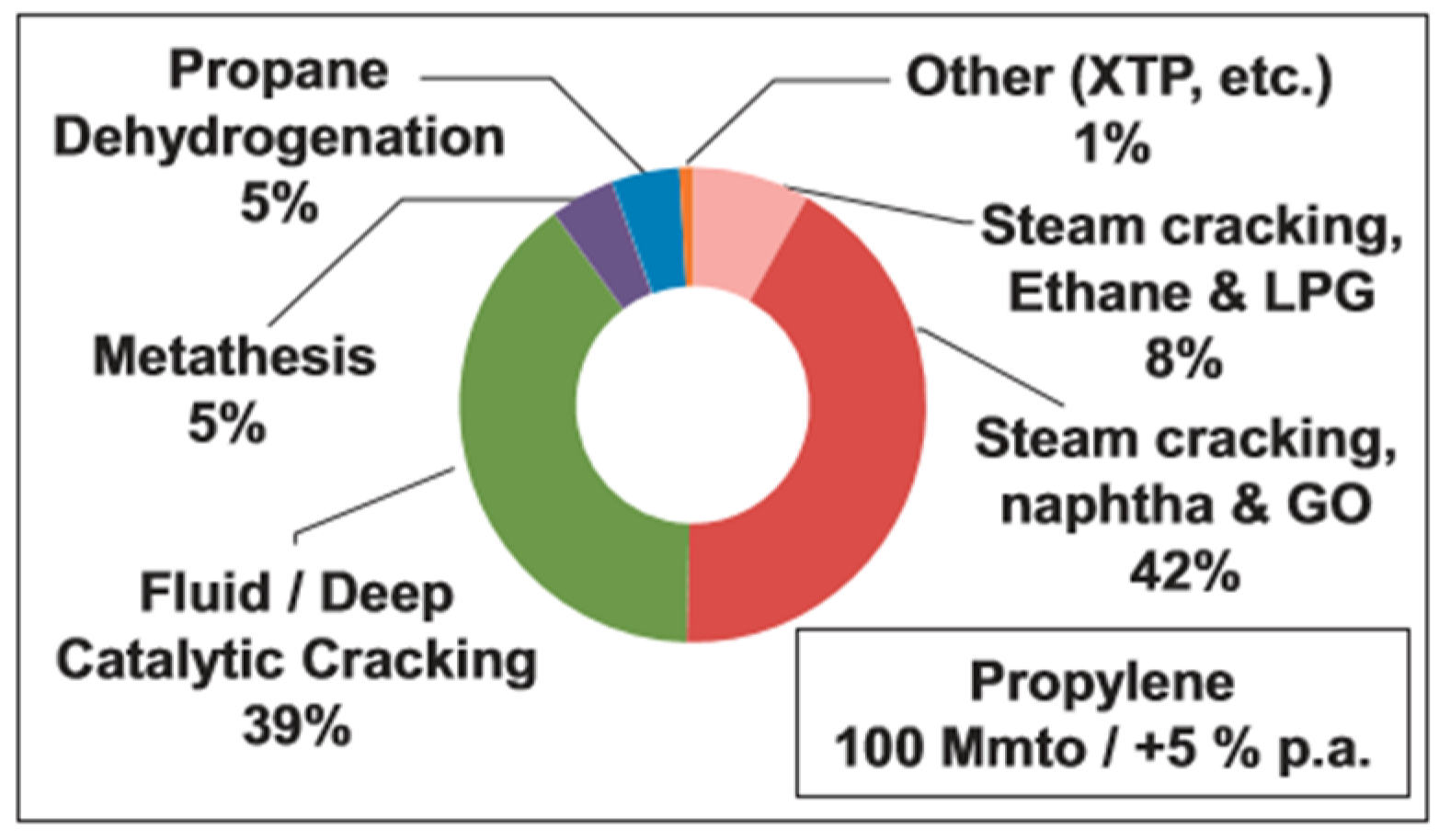

Naphtha and gas cracking for production of olefins.

Ethane cracker process flow diagram. Can be cracked to produce ethylene. Process flow diagram for ethane cracking. Ethylene from renewable sources.

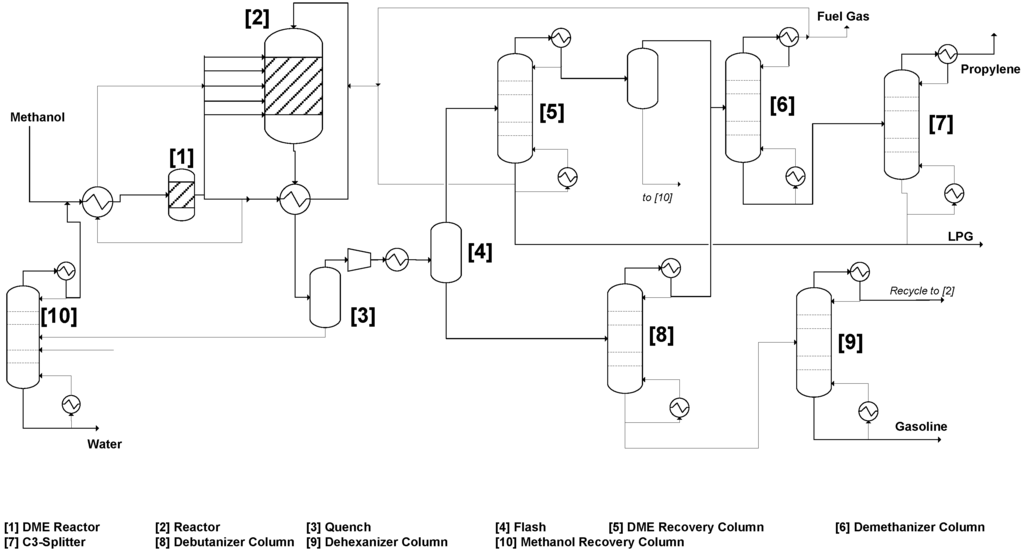

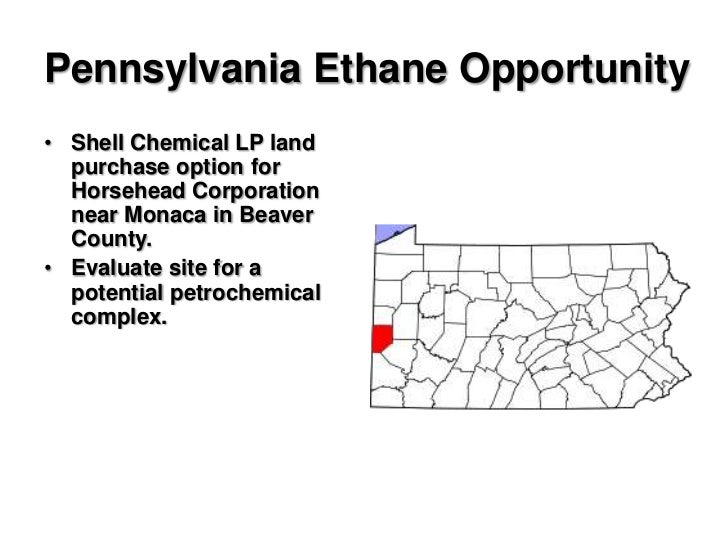

Process flow diagrams and descriptions for uop exxonmobil and dalian institute of chemical physics dicp technologies are given. About these slides the slides in this collection are the talking points that guided our discussion at the 2012 pa wib symposium with approximately 40 symposium participants. The content and flow of the slides provides an outline of our remarks but not their detail.

Steam cracker 170 mw heat duty modeled as 2 100mw separate pyrolysis furnaces each furnace 100 mw capacity operates at 80 capacity. Naphtha ethane propane gas oil etc. Normal operation assumes five furnaces continuous operation and one furnace on hot stand by or decoking operations.

Linde 713 873 1708. An ethylene steam cracker can accept a variety of feedstock. Cracking the ethane cracker.

In the convection zone hydrocarbon feed stock. The ethane crackers fuel consists of a mixture of recycled tail gas hydrogen rich and natural gas methane with a heating value of 523 btuscf. A mixture of inert steam and hydrocarbon feed stocks are entered into coiled tubular reactors with high temperatures and short residence times.

Hot section it consists of convection zone and radiant zone. The process shown in figure 1 is a steam cracking process for ethylene production from an ethane propane mixture. The use of ethanol to make ethylene on a comparatively small scale is well established in developing countries not having ready access to hydrocarbons.

Flow diagram for pyrolysis of napththa is given in figure m vii 21. The choice of feedstock can depend on the cracker furnace construction the availability of the particular feed its current market price and the desired end products. In the case of steam cracking of the ethane and propane it is convenient to.

Advances in ethane cracking. The olefins are widely produced using thermal cracking of light hydrocarbons such as ethane propane n butane and their mixtures. The process can be divided into three main parts.

Process Economics And Safety Considerations For The Oxidative

Ethylene Plant Design Considerations

Ethylene Plant Design Considerations

Deciphering The True Life Cycle Environmental Impacts And Costs Of

Deciphering The True Life Cycle Environmental Impacts And Costs Of

The Effect Of Operating Conditions On Corrosion In Hf Alkylation Units

The Effect Of Operating Conditions On Corrosion In Hf Alkylation Units

Ethane Cracker Process Flow Diagram

Processes Free Full Text A Techno Economic Comparison Between

Processes Free Full Text A Techno Economic Comparison Between

Cracking And Related Refinery Processes

Detailed Modelling And Optimisation Of An Ethylene Plant Chemical

Engine Ethane Cracker Plant Process Flow Diagram Thebuffalotruck Com

Engine Ethane Cracker Plant Process Flow Diagram Thebuffalotruck Com

Methanol To Olefins Mto From Fundamentals To Commercialization

Lurgi Mtp Simplified Process Flow Diagram 9 Download Scientific

Lurgi Mtp Simplified Process Flow Diagram 9 Download Scientific

Process Design For The Production Of Ethylene From Ethanol

Process Economics Program Pep Steam Cracking Of Crude Oil

Ngl 101 Ethylene As Chemical Royalty Pipe Up

Ngl 101 Ethylene As Chemical Royalty Pipe Up

Nptel Chemical Engineering Petroleum Refinery Engineering

Nptel Chemical Engineering Petroleum Refinery Engineering

Mathematical Modeling Of Ethane Cracking Furnace Of Olefin Plant

Mathematical Modeling Of Ethane Cracking Furnace Of Olefin Plant

0 Response to "Ethane Cracker Process Flow Diagram"

Post a Comment